KROFTA ENGINEERING LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to KROFTA ENGINEERING LTD.

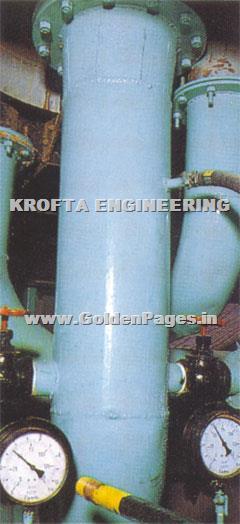

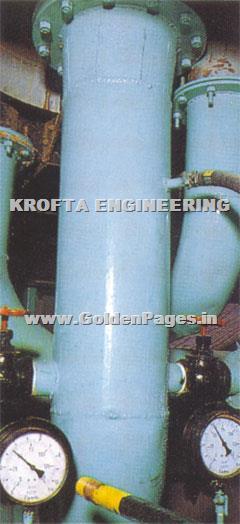

Air Dissolving Tube

Raw recycled water enters the “KROFTA” AIR DISSOLVING TUBE tangentially at one end, pressurized

to 4-6 bar, which is discharged at

the opposite end. During the short passage the water rotates in side the tube and passes repeatedly by an

insert which is fed by compressed

air. Very thorough mixing under pressure dissolves the air in the water which is released to atmospheric pressure in the floatation cell. Suspended solids flocculated with the help of flocculants attach themselves to the air bubbles and come to the surface to form the sludge.

The patented “KROFTA” SPIRAL SCOOP takes up the floated sludge, pouring it into the stationary centre section, from where it is discharged by gravity, either for recycling or disposal.

Clarified water is removed through extraction pipes which are connected to the moving centre section. Part of the clarified water passes through the “KROFTA” AIR DISSOLVING TUBE before joining the mainstream of unclarified water. The clarified water extracted from the process normally contains less than 30 ppm of suspended solids. It can be recycled in the process or sewered.

Wiper blades attached to the moving distribution duct scrape the bottom and the sides of the tank and discharge the settled sludge into the built in sump for periodic purging.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.